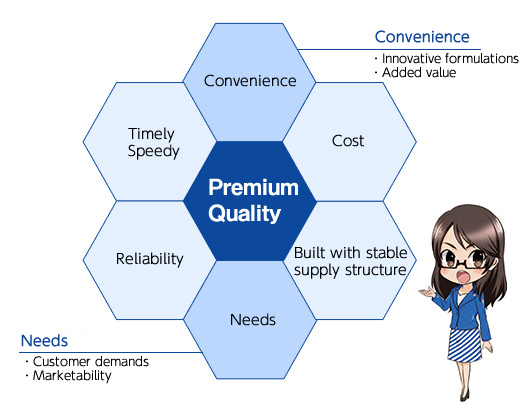

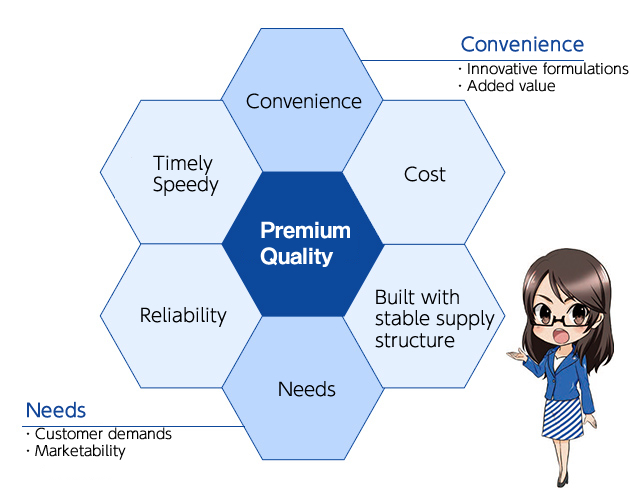

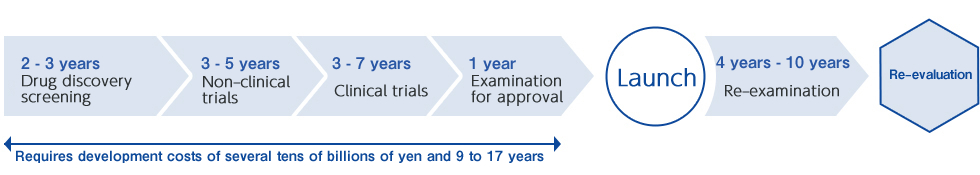

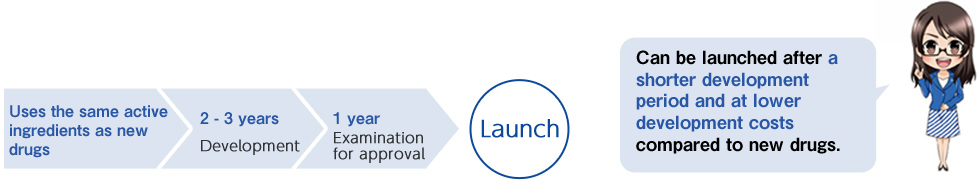

Process up to completion of a Nichi–Iko generic drug

Generic drugs can be launched in a shorter development period and at lower development costs compared to originator drugs (new drugs). However, many processes described below are required up to the launch of the generic drugs.

・New drug

・Generic drug

Development process for a Nichi–Iko generic drug

- Patent search

- Selection of

development items

- Selection of

drug substances - Consideration of

formulations - Manufacturing of

investigational

drugs

- Consideration of

analytical methods - Stability test

- Bioequivalence study

(dissolution test)

- Bioequivalence study

(human BE study)

- Consideration of

industrialization

Step1 Patent search, selection of development items

Development and Planning Department

Step2 Selection of drug substances, consideration of formulations, manufacturing of investigational drugs

Formulation Development Department

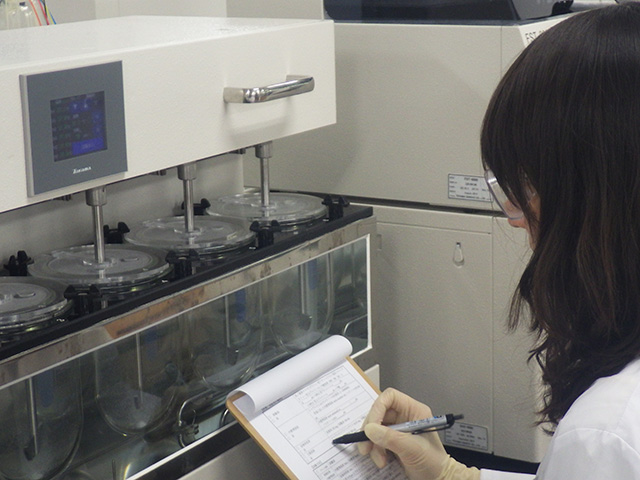

Step3 Consideration of analytical methods, stability test, bioequivalence study (dissolution test)

Product Test Department

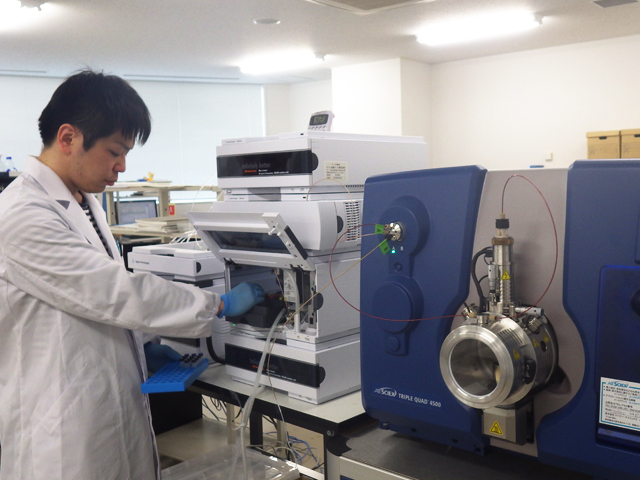

Step4 Bioequivalence study (human BE study)

Clinical Test Department

Step5 Consideration of industrialization

Production Technology Department

Ensure reliability (audit of application dossier)

Test audit group, GCP audit group